TRUCK WHEEL ALIGNMENT DIAGNOSIS

Spot and pre-empt common alignment issues and what actions can be taken to rectify those issues.

Tyre wear can be an indication of alignment issues however only when the list of pre-requisites and a full measurement is done can the vehicle be diagnosed properly. We often see vehicles being diagnosed without proper due-diligence or incorrect setup of equipment for example measuring on an uneven floor could drastically impact results. When measurements are so fine the setup and process have to be perfect.

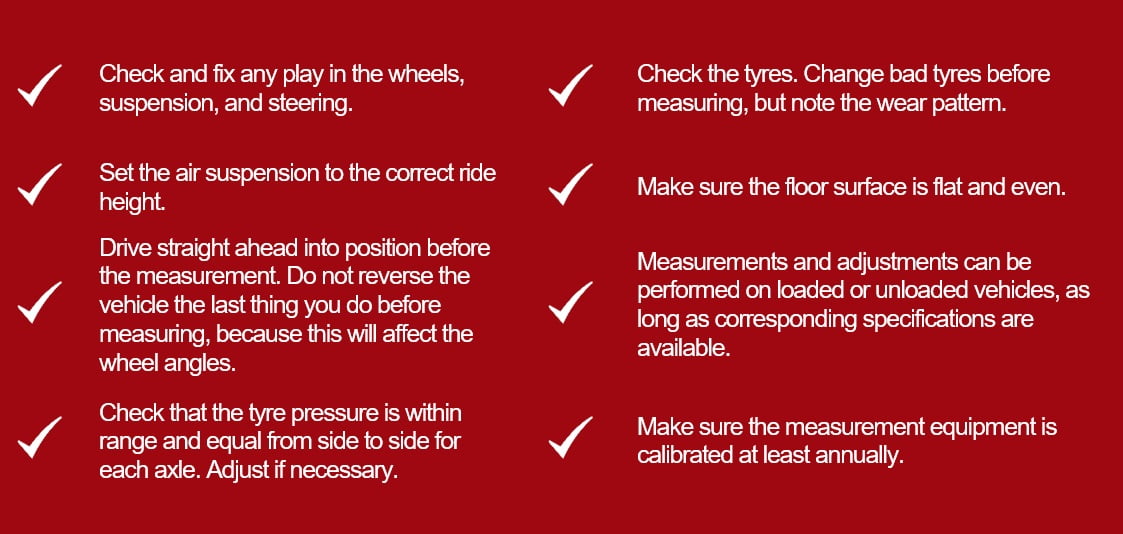

AES PRE-REQUISITE TIPS FOR ALIGNMENT

Ensure that whoever is responsible for your wheel alignment is checking the below before any wheel alignment is carried out, these factors can change the geometry of a vehicle so it’s imperative to check them.

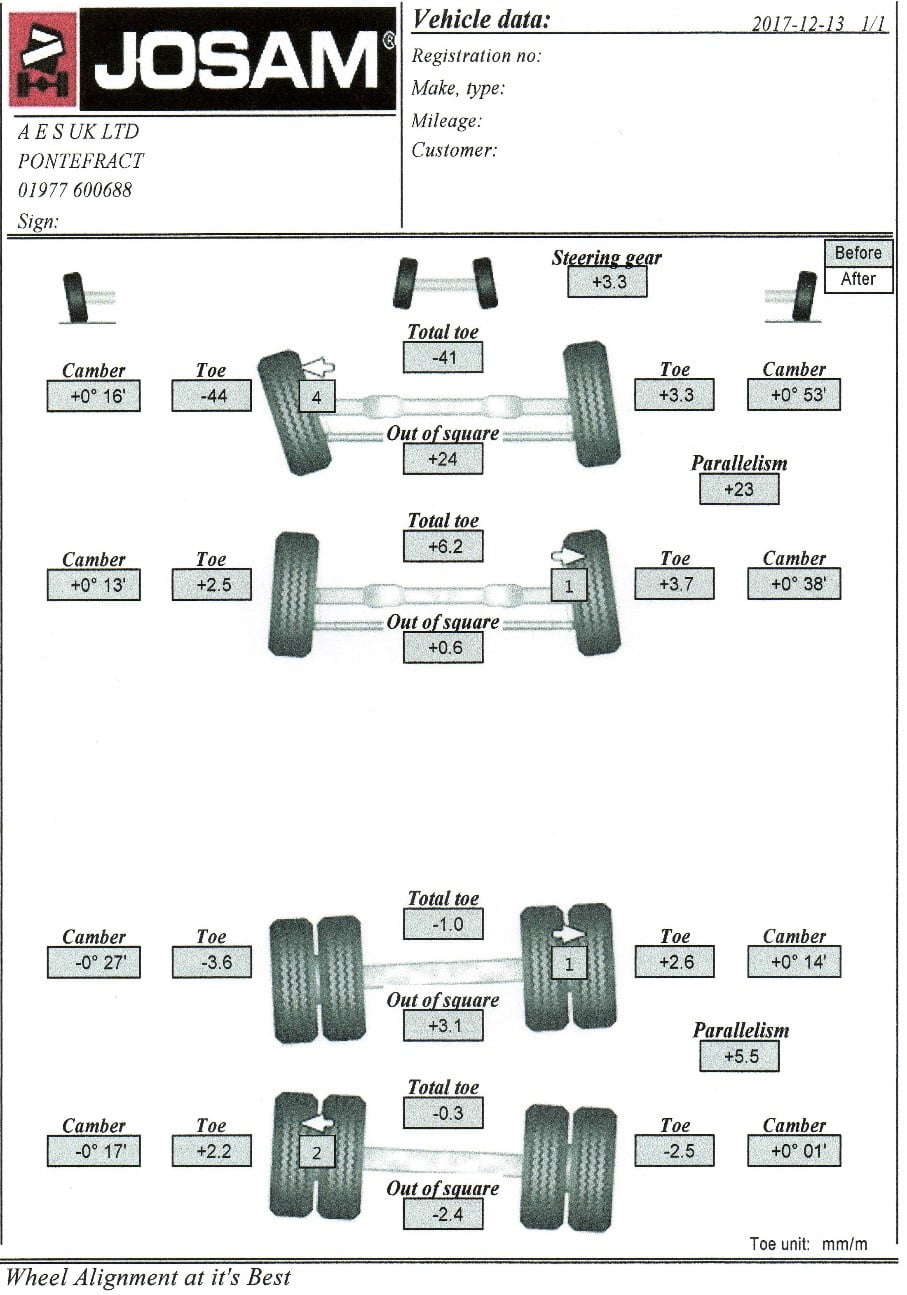

FULL VEHICLE PICTURE

We see front-steered axles receiving the most attention during the measurement process, and quite often the only axle measured. With 80% of front tyre issues caused by the rear axles, AES strongly advise that a full vehicle measurement is performed before diagnosing. Contrary to popular belief most rear axles can be adjusted through various methods such as shimming ensuring that the full vehicle can be adjusted to run straight.

TRAILERS

Quite often semi-trailers get forgotten when it comes to wheel alignment, owner-operators tend to focus on tractor units but what is the effect of a misaligned trailer on a tractor unit?

- Excessive wear on truck and trailer tyres

- Increased fuel consumption due to additional drag

- Potential handling and braking problems

- Crabbing across the road – taking up more of the lane

LOADED OR UNLOADED

Ideally measurements would be taken with a vehicle laden to replicate how the vehicle runs naturally when transporting goods, unfortunately, this is often not possible therefore measurements and adjustments have to take this into account. On steered axles, toe-in is needed to counteract the tendency of the wheels to roll outward as a result of the positive camber. On a rear-wheel-drive vehicle, the road friction also pulls the wheels on steered axles outwards when driving. Drive axles usually have a slight toe-out, because the drive wheels are pulled inwards when driving. This is dependent on the axle and suspension type.

HGV ALIGNMENT Equipment

Josam is the industry standard when it comes to HGV wheel alignment equipment, many of the mobile alignment companies use Josam equipment which defines how robust the equipment is.

For companies/individuals looking at purchasing wheel alignment equipment AES UK have compiled some considerations;

- Purpose – is the purpose of the equipment to go out mobile? Carry out 1 alignment per week? Or large-scale alignments?

- Demo – choose a complex vehicle to measure for a demo and use the same vehicle for all demos for a like-for-like comparison

- Easy to use – Should be straightforward to training technicians, setup, measuring and adjusting

- Flexible – All vehicle types and setups should be covered

- Quick & Accurate – To diagnose and more importantly to fix the issues

- Value – Ensure the equipment complies with the above and pays for itself quickly

- Training & Aftersales support – what does the aftersales support look like?

- Quality – robust equipment that can withstand the harsh environments and is easily maintained

JOSAM Equipment

Josam equipment supplied by AES UK Ltd have a range of solutions to suit all businesses looking to purchase wheel alignment equipment. Josam wheel alignment product range includes;

- Josam Laser AM – Manually operated Laser system

- Josam Cam-aligner – Quick, easy-to-use flexible camera system

- Josam I-Track – Dedicated workshop bay for large scale alignment

We understand that the equipment is only as good as the technicians using it, this is why they provide onsite bespoke training and video call support with every wheel alignment package.

Additionally, we have developed a return on investment calculator to help your business understand how long the equipment takes to pay for itself.