HGV Wheel Alignment Systems

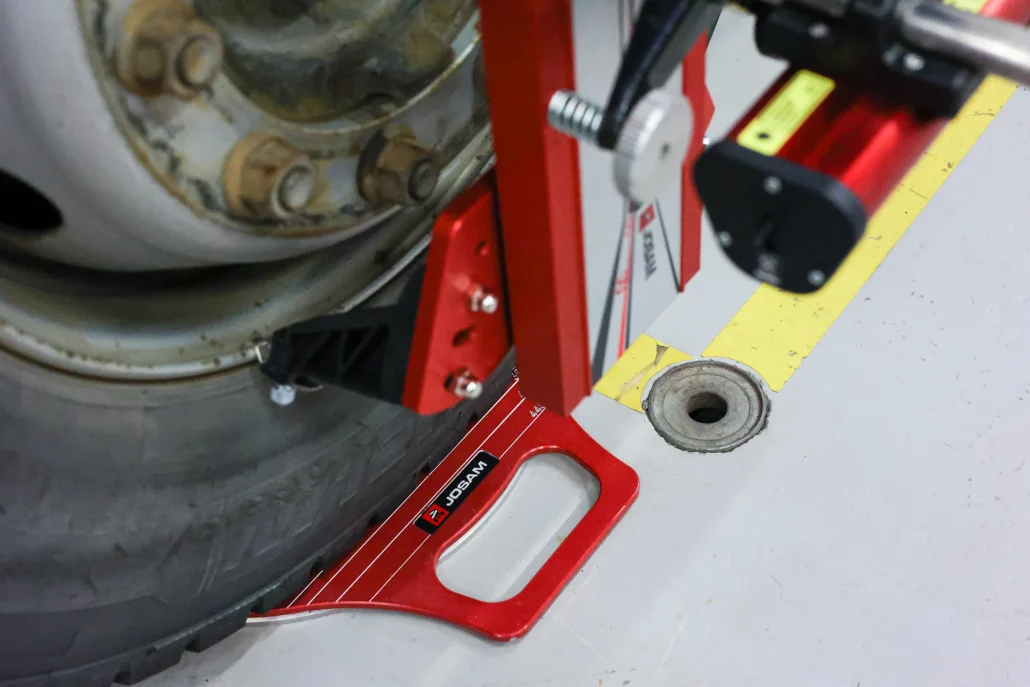

If you’re looking for HGV wheel alignment equipment Josam is the industry standard. Our equipment work from a centreline using wheel alignment tracking gauges that hang from the chassis, or in the I-track’s case are in a fixed position on the floor. All our HGV vehicle aligners come with heavy duty turn plates and robust measuring equipment.

The wheels/axles of a commercial vehicle are arguably the most important part. Getting the most out of your vehicle requires correct maintenance. For optimal performance, your vehicle should regularly undergo wheel alignment diagnosis and adjustment when required.

Commercial wheel alignment is setting the angle of the wheels on commercial vehicles such as truck, bus and van, so they track in the right direction. Most commercial vehicles come with individual wheel alignment settings meaning; each of the axles of the vehicle have to be separately aligned.

Common causes of mis-aligned commercial vehicle axles are:

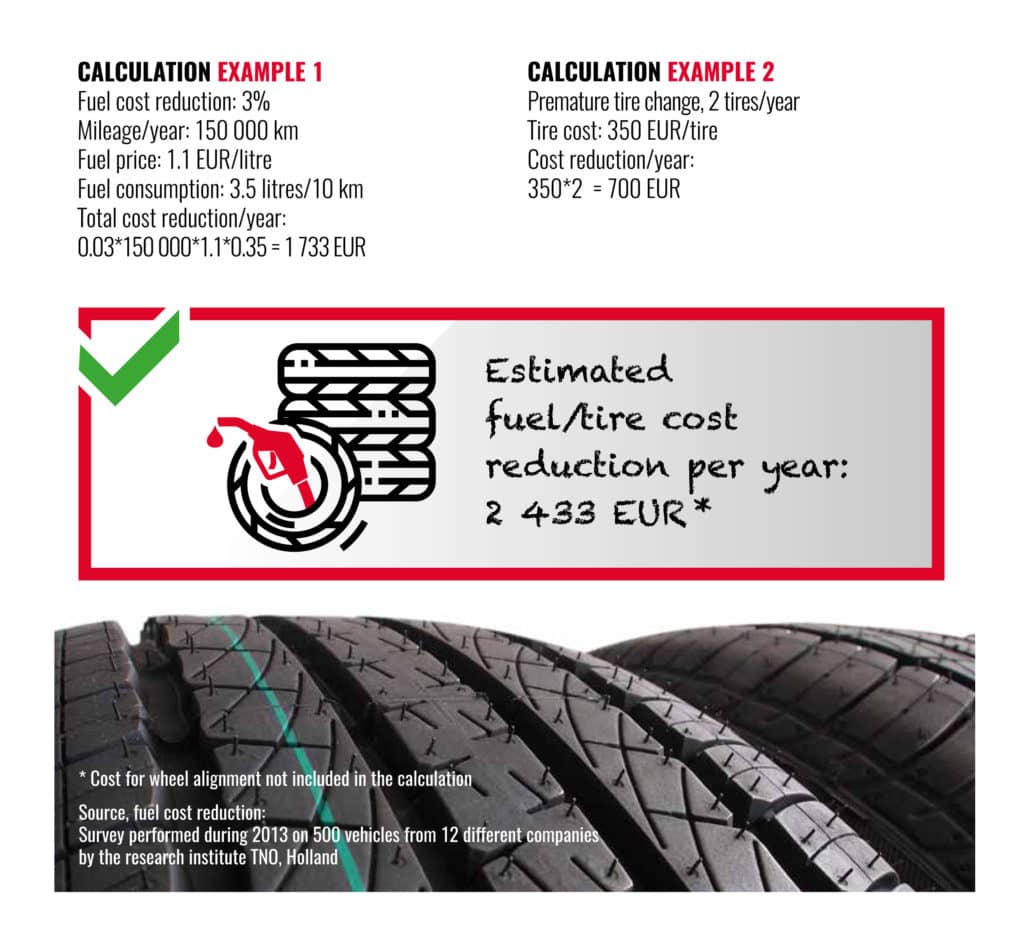

Save on fuel and tyres with correct wheel alignment settings

Proven fuel savings with correct wheel alignment – Volvo trucks carried out an isolated test on correctly aligned commercial vehicles against incorrectly aligned vehicles using Josam / TruckCam equipment. The tests showed correctly aligned vehicles can reduce fuel consumption by 2.5%. The tests also showed that should the truck have incorrect tyre setup (type of tyres and air pressure) the fuel savings could be up to 15%. A real life case study can be found here.

Commercial Vehicles Our Equipment Can Measure

At AES, we offer industry standard HGV wheel alignment equipment for all commercial vehicles such as:

- HGV Wheel Alignment equipment – Heavy goods vehicles (HGV) trucks, semi-trailers, tractor units, semi-trailer trucks.

- Bus Wheel Alignment – Public service vehicles (PSV)

buses (diesel, hybrid, electric) and coaches. - Van Wheel Alignment – Light commercial vehicles (LCV)

vans and pickups 4 x 4’s. - Plant Vehicles, earth movers, graders, cranes.

- Farm vehicles, tractors, combines, seeders.

What Are The Benefits of HGV wheel alignment

Getting your truck, bus or van wheel alignment done regularly is very important to both the tyres and overall handling of your vehicle. Here are a few other reasons why getting your wheels/axles aligned is important:

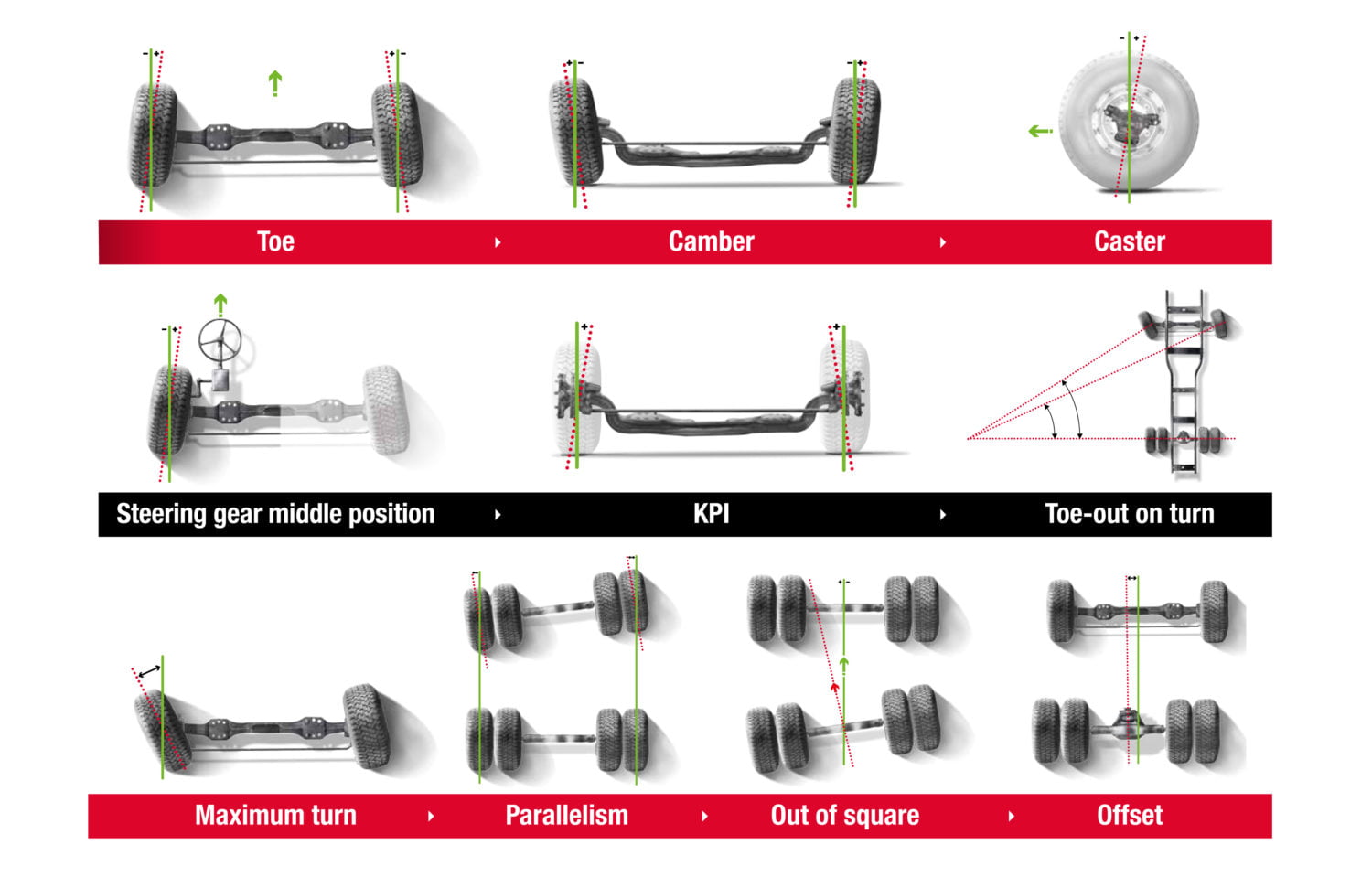

HGV Wheel Alignment Measurement Angles

Wheel Alignment Terminology

Camber: is the tilt of the tyre when viewed from the front of the truck. Insides of tyres tend to wear prematurely on vehicles with too much negative camber on the other hand too much positive camber will wear the outside tread.

Caster: simply is the inclination of the front spindle. When the caster is out, it creates a pull or wandering condition and sometimes a slow responding steering wheel.

Toe: is measured in degrees & minutes . When viewing the truck from the front, it is the difference between the front and rear center-line of the tyre. Toe-in means the fronts of the tyres are closer together. While toe-out means, the fronts of the tyres are further apart. Toe-in or out have the most effect on tyre wear.

Thrust angle alignment / Out of square: The thrust angle is an imaginary line drawn perpendicular to the rear axle’s centerline. To measure the thrust angle on a vehicle you have to perform individual wheel alignments. Even if the rear axle is non-adjustable, you need to take rear axle readings to properly align the front suspension

Steering gear middle position: Steering box position is simply the fact that the steering wheel is centered when the vehicle is traveling down a straight and level road. Assuming that the steering wheel stays in the same position when you let go of the wheel (in other words, the car is not pulling), then steering center is controlled by the front and rear toe settings

Maximum turn: The measurement of distance between the center line and max steer (left and right) or full lock.

Parallelism: Parallelism is when you have 2 axles and it takes the toe difference’s between both axles.

Axle offset: Axle offset is how axle centres are in relation to the centre line of the vehicle.

Toe out on turn: The toe-out on turns is the angle of the inner wheel to the outer wheel when negotiating bends. The steering is constructed so that the angle of the wheels to one another changes with an increased steering angle.

KPI: The angle formed by a line drawn through the upper and lower pivot points of the steering axis and a vertical line as viewed from the front

What Types of HGV Wheel Aligners Are Available?

Camera-based Commercial Wheel Alignment Equipment

Our camera-based digital, wireless commercial wheel aligner is the only multi-OEM approved heavy vehicle wheel aligner on the marker. Approved by Scania, Renault, Volvo and Mercedes.

Laser Commercial Vehicle Wheel Alignment Equipment

The Josam Laser AM is the industry standard analuge commercial vehicle wheel aligner which can be used inside or outside and can be used with or without software. The laser HGV wheel aligner is our most robust kit.

Wheel Alignment FAQs

How often should I perform truck alignment?

Alignments should be carried out at least once per year, preferably 3 to 4 times per year to pre-empt any issues.

Check out our full post about this here: https://a-e-s-uk.co.uk/news/how-often-commercial-vehicle-alignment/

How long does it take to do an alignment on a truck?

Depending on the equipment used measurements can be done in under 4 minutes with the Josam I-Track. The vehicle configuration also plays a part, for example a truck with 4 axles will take longer than measuring only 1 axle. Adjustment times also vary depending on what needs to be adjusted.

How do I know if my truck is out of alignment?

If you have tyre wear issues it could mean your truck is out of alignment. If you experience a pull to one side or the other this could also indicate misalignment.

What are the effects of truck misalignment?

- Increased fuel consumption – a small misalignment can increase fuel consumption by up to 5%

- Increased tyre wear – a small misalignment can reduce tyre life by 50%

- Increased mechanical wear

- Reduced uptime – due to increased risk for unplanned stops

- Poor driving comfort and drivability – which could lead to accidents and work-related injuries

- Decreased safety – due to poor drivability and large required space on the road. Uneven tyre wear can also decrease safety

- Increased environmental impact through increased fuel consumption

what should I check before doing a truck alignment?

- Check and fix any play in the wheels, suspension, and steering.

- Check the tyres. Change bad tyres before measuring, but note the wear pattern.

- Set the air suspension to the correct ride height.

- Make sure the floor surface is flat and even.

- Drive straight ahead into position before the measurement. Do not reverse the vehicle the last thing you do before measuring, because this will affect the wheel angles.

- Measurements and adjustments can be performed on loaded or unloaded vehicles, as long as corresponding specifications are available.

- Check that the tyre pressure is within range and equal from side to side for each axle. Adjust if necessary.

- Make sure the measurement equipment is calibrated at least annually.

What are the benefits of truck alignment?

- Reduce fuel consumption – a correction of alignment can increase fuel consumption by up to 5%

- Reduce tyre wear – a correction of alignment can increase tyre life by 50%

- Increased driving comfort and drivability

- Improved environmental impact through increased fuel consumption

What causes trucks to go out of alignment?

- Driving over something, a collision, curbing or driving on rough terrain

- Replacement of suspension parts or steering components

- Worn, damaged or bent suspension parts

- Wheels and tyres being worn or replaced incorrectly

- Added or reduced weight to the chassis/body

Does changing truck wheels affect alignment?

It can. If a new truck tyre is fitted it will alter the geometry of the vehicle, this is why we recommend diagnosing a truck after a new tyre has been fitted.

How much is an alignment for a truck?

Cost is usually £80/axle. Prices vary depending on a number of circumstances such as axles aligned, axle configuration and also adjustments needed.

What is an alignment on a truck?

Alignment refers to the process of measuring, diagnosing and adjustment of components that connect the vehicle to its wheels.