Aligning the wheels of a commercial vehicle involves adjusting the angles of the wheels to ensure they are perpendicular to the ground and parallel to each other. The process is typically performed by trained technicians using specialised equipment. Here’s a general overview of how an alignment is done on a truck:

1. Inspection: The alignment process begins with a thorough inspection of the commercial vehicles tyres, suspension components, and steering system. The technician will look for signs of wear, damage, or any issues that might affect the alignment.

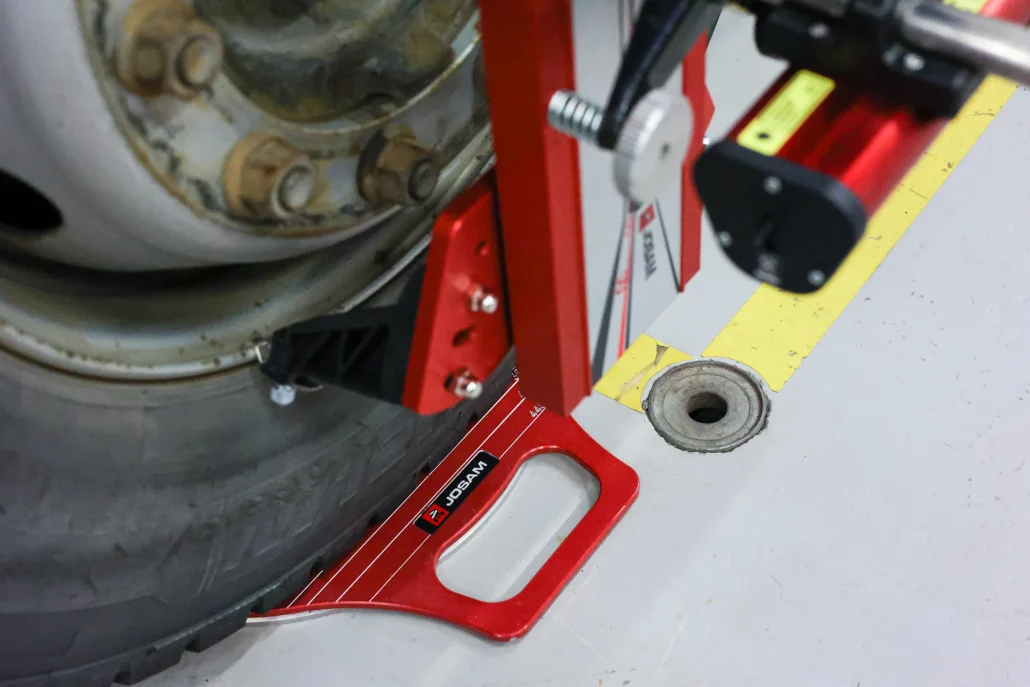

2. Alignment Equipment Setup: The truck is positioned on an inspection pit, which allows easy access to all wheels. The alignment machine is attached to the wheels, providing real-time data on the current wheel angles.

3. Wheel Measurement: The alignment machine uses lasers or cameras to measure the current angles of the commercial vehicle’s wheels. The primary alignment angles measured are toe, camber, and caster.

Toe: The angle at which the tires point inward or outward when viewed from above.

Camber: The angle of the tires concerning the vertical axis when viewed from the front.

Caster: The angle of the steering axis concerning the vertical axis when viewed from the side.

4. Adjustments: Based on the measurements obtained, the technician will determine if any adjustments are needed. Alignment adjustments are made using specialized tools to manipulate the truck’s suspension components.

Toe Adjustment: To correct toe alignment, the technician will adjust the tie rods to ensure the tires are parallel to each other.

Camber Adjustment: Camber is adjusted by changing the position of the upper or lower control arms or using specialized camber adjustment kits.

Caster Adjustment: Caster adjustments are made by altering the position of the upper control arm or using adjustable ball joints.

5. Recheck and Fine-Tuning: After the initial adjustments, the technician rechecks the alignment angles to ensure they are within the manufacturer’s specifications. Fine-tuning may be done to achieve the desired alignment settings accurately.

6. Test Drive: To confirm that the alignment is correctly done, the truck is taken for a test drive. The technician checks for any abnormal handling or steering behavior and ensures that the truck drives straight without pulling to one side.

7. Final Report and Recommendations: A final alignment report is generated, providing details of the initial and final alignment settings. If any additional repairs or replacements are recommended during the alignment process, the technician will inform the truck owner or operator.

Proper wheel alignment is crucial for commercial vehicles to ensure safety, tire longevity, and optimal vehicle performance. It’s recommended to have a truck’s alignment checked regularly and after any suspension or steering system work to maintain its efficient operation on the road.